Quality Assurance

QUALITY ASSURANCE

At Tirupati Plastomatics, quality is not just a product centric vision but an Omni-organizational vision. With a firm belief that quality begins and ends with people, the management has inculcated a quality culture in the very thought process of the organization.

Quality at Every Step

At Tirupati Plastomatics our philosophy on quality is simple — meet or exceed our clients expectations through continuous quality improvement and by building our work right the first time.

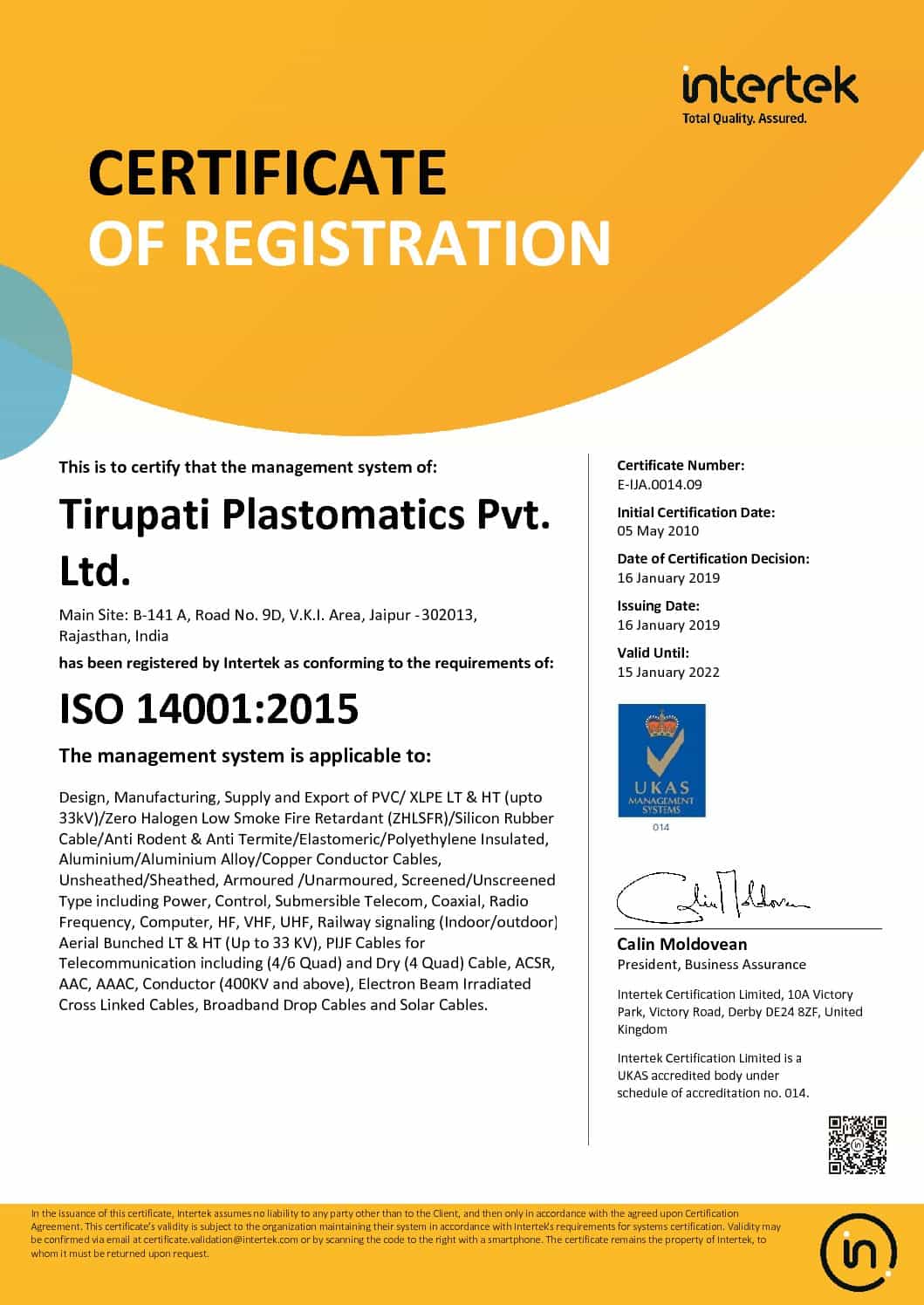

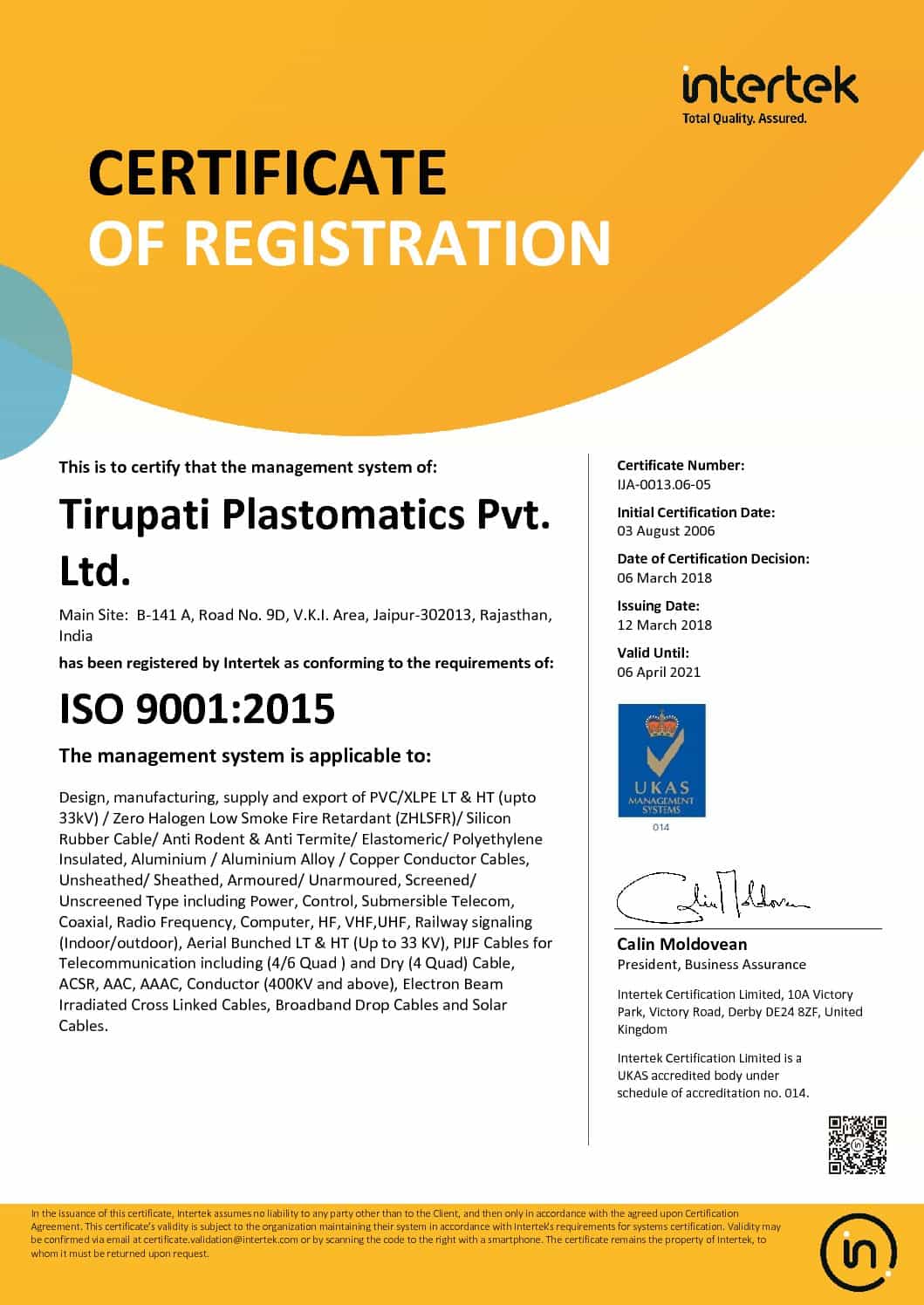

Certificates

Tirupati Plastomatics CABLES RECOGNIZES THAT THE DISCIPLINES OF QUALITY, HEALTH, SAFETY AND ENVIRONMENTAL MANAGEMENT ARE AN INTEGRAL PART OF ITS MANAGEMENT FUNCTION. The company views these as a primary responsibility and to be the key to good business in adopting appropriate Quality, Health, Safety and Environmental standards.

Company puts its vision to be customer’s first choice in both local & foreign markets, which leads to produce Cables and execute projects with the best Quality standards and conforming to international standards & customers' requirements.

Quality Assurance

Internal & External Inspection

The Internal & External Inspection provides information regarding the overall condition of the products.

Final Product Testing

Final Product Testing is a process of measuring the properties or performance of products.

In-Process Inspection and Testing

This process provides the redundancy necessary to prevent any quality problem from evading detection.

Incoming Raw Material Testing

This is a crucial step in every industry to assure that the correct raw material which meets the quality specifications has been received.

Vendor Evaluation

Vendor Evaluation supports you in optimizing your procurement processes for both materials and external services.

Quality Policy

Background

TPPL Management is committed to complying National or International standards for manufacturing of Cables. This policy is publicly available and communicated throughout the business.

Scope

This policy applies to all products manufactured by TPPL.

Policy

TPPL Strives to achieve customer delight by timely supply of Quality products at competitive price focusing on continual improvement in Product, Process and System.

TPPL Introduce & Implement sound QMS (Quality Management System) in all our activities and monitor, review and improve the Product quality through continual improvement process.

Quality Objectives

TPPL ensure that this policy will be maintained by achieving following quality objectives

- To strive to increased Turnover & profitability by Min. 5% in every year ending 31st march.

- To maintain existing level of zero customer complaints by meeting sales targets & production efficiency targets on the quality of the product.

- To impart a minimum of 5 hours of training per year to each new operator in works or lab assistant to improve their skill, knowledge and competence & provide training to each employee as per training calendar of the year.

- To reduce Reject/Rework & cost of quality by down timing of the critical machine’s namely – Extruders to a maximum period of one week per year through timely preventive maintenance program.

- To ensure no delay in delivery of the existing range of products viewing timely delivery as one of the tenets of the quality policy.

Client testimonial

Mr. Ovijeet Das

Overseas Infrastructures Alliance (OIA) India Pvt. Ltd.

“After the delivery of the cables against one of our RURAL ELECTRIFICATION (RE) project in Mozambique, TIRUPATI PLASTOMATICS TEAM was very apt in rendering the on-site training support related to installation aspects to our staff people which is exemplary and made our task lot more easier. We appreciate their POST SALES SUPPORT which was not a part of our contract agreement.”

Mr. I.P. Sharma

IRCON International Limited

“QUALITY is of paramount importance to our company and we are quite satisfied with the on-field performance of TIRUPATI PLASTOMATICS cables installed in our project”

Mr. Bharat Kulkarni

Hitachi Rail STS

“During the Pre-shipment inspection, we realized that the quality of workmanship of TIRUPATI PLASTOMATICS make cables is of highest quality. Their labs are fully equipped to perform all the ACCEPTANCE TESTS which were desired from our side. We would come back for the repeat purchase of the similar cables”

Ms. Nirmal

Delhi Metro Rail Corporation (DMRC

“Our Experience of buying the cables for our Metro Project had been very satisfying as they are operationally performing well in line with our desired standards. We vouch for the technical prowess of TIRUPATI PLASTOMATICS make cables.”

Dedicated Customer Terms & An Agile Service

Our worldwide presence ensures the timeliness, cost efficiency and compliance adherence required to ensure your production timelines are met.

Download Brochures

LV Cable Catalog MV Power Cable Catalog MVCC CatalogRequest a Quote

Complete control over products allows us to ensure our customer receive the best quality price and service. we take great pride in everything that we do in our factory.